Polytek Building Solution

INNOVATING - FLOORING SYSTEMS

Deckshield: Two components PU Coating Systems with Zero solvents, flame retardant and long term protection. These are resistant to chemicals, antimicrobials, high impact strength with good abrasion resistant. Deckshield are Durable and reliable flooring option for your parking deck or industrial space. Deckshield are made with 100% solid polyurethane, Deckshield Flooring is designed to withstand heavy traffic and harsh industrial conditions.

Durable and Long-Lasting

Deckshield flooring is built to last, providing a strong and sturdy surface that can handle even the toughest environments.

Perfect for Parking Decks

With its high resistance to abrasions and chemicals, Deckshield flooring is the ideal choice for parking decks, ensuring a safe and reliable surface for vehicles.

Industrial Strength

Designed to withstand heavy machinery and equipment, Deckshield flooring is the perfect solution for industrial spaces, providing a strong and durable surface for daily operations.

Specifications

- Made with 100% solid polyurethane

- Highly resistant to abrasions and chemicals

- Suitable for heavy traffic and industrial use

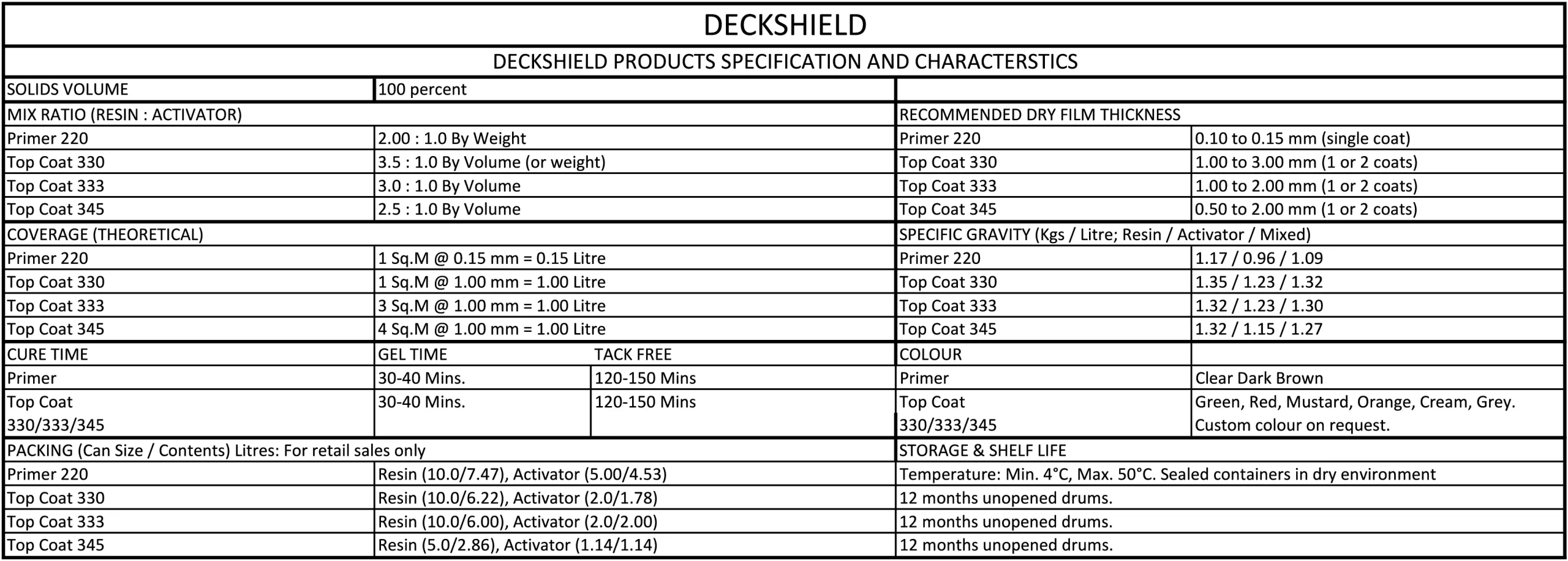

Deckshield Products Specification and Characterstics

How It Works

Prepare the surface by cleaning and ensuring it is dry and free of any debris

Mix the Deckshield flooring components according to instructions.

Apply the mixture to the surface using a trowel or roller.

Smooth out any air pockets and allow to dry for the recommended time.

Deckshield Performance Values

Property | ASTM Standard | 330 | 333 |

Hardness, Shore D | D 2240-15(21) | 75 Shore D | 82 Shore D |

Elogation @ Break | D 638-14 | 146.00% | 21.00% |

Tensile Strength | D 638-14 | 3,060 Psi or 21.1 N/mm² | 5,350 Psi or 36.90 N/mm² |

Compressive Strength | C579-18 | 18,719 psi or 129.0 N/mm² | 18,814 psi or 129.7 N/mm² |

Impact Strength | D2794-93(19) | Direct : 56 in-Ib or 6.32 J | Direct : 75 in-Ib or 8.47 J |

Abrasion Resistance | D 4060-19 | 109mg | 122 mg |

Water Absorption | C413-18 | 0.355% | 0.248% |

Linear Shrinkage & Coeff. Of Therm. Expan. | C531-18 | 0.129(%) | 0.088 (%) |

Flexural Strength & Modulus of Elasticity | D 790(17) | 2,464 Psi or 17.0 N/mm² | 7,404 Psi or 51.05 N/mm² |

VOC Content | D 2369-20 | 0.01 Ib./ Gallom or 1.20 gms./ Litre | 0.00 Ib./ Gallom or 0.00 gms./ Litre |

Chemical Resistance | 07 Days | 30% NaOh = 0.20% loss | 30% NaOh = 0.08% loss |